Helping wells go with the flow

How real-time flow monitoring could help deliver more-productive wells.

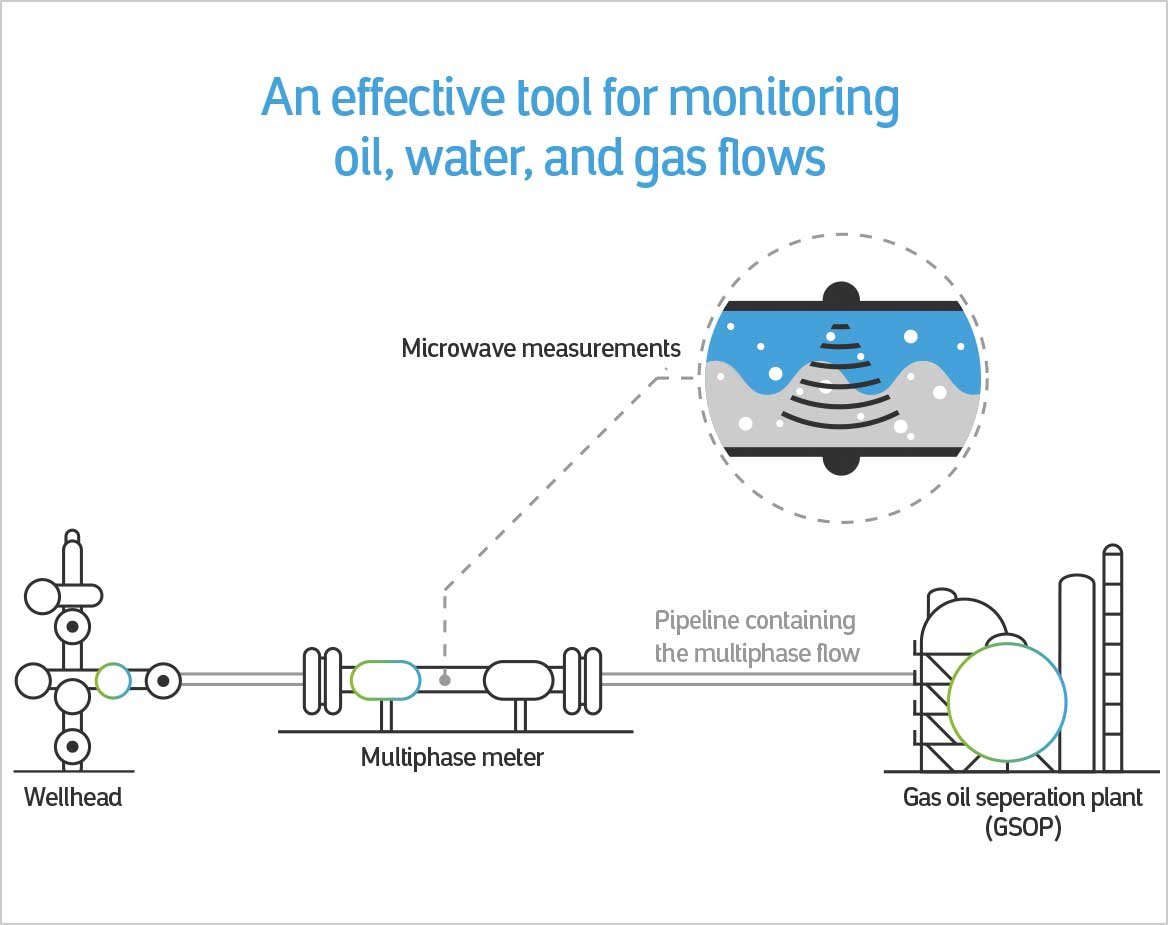

- Accurate flow monitoring is vital to gain a clear picture of the composition of each well, which can help us to maximize hydrocarbon recovery

- Aramco’s AI-assisted microwave resonance-based meter could provide more accurate real-time data than ever before

- The innovation draws on Aramco’s expertise in Fourth Industrial Revolution technology

For millions of years, oil, gas, and water have been trapped in reservoir rocks deep below the earth’s surface. Conventional reservoir rocks are porous and permeable, but the overlying rocks are not, which keeps the hydrocarbons in place.

Once we have found these reservoirs and drilled into the rock, extracting the oil and gas also means bringing up the water, too. The oil, gas, and water come out of the well in what is called a multiphase flow; including a binary liquid phase — oil and water — and a gas phase.

Finding the right fit

Too much water coming out of the well can cause corrosion, scaling, and other damage in equipment and pipelines. It is also expensive to properly treat and safely dispose of this water. Making things more complicated is the fact that the water cut — the ratio of water produced to the total volume of liquids produced — can change suddenly and without warning.

To ensure the well is running efficiently in this case means the multiphase flow must be monitored constantly. This is done with a tool known as a multiphase flow meter, which helps engineers assess the productivity of the well and then optimize production for better reservoir management.

That might mean injecting water or steam to keep a depleted reservoir productive, or drilling infill wells to target additional pockets of oil. In some cases, the fluid flow will show that there isn’t a strong business case to continue working a particular well. This is due to insufficient hydrocarbons being extracted to justify the cost of the operation.

Knowing this as soon as possible can save huge amounts of effort and money, so having the right measurement tool is vital. Aramco is leveraging its expertise, technology investment infrastructure, and global research network to design and build a more efficient tool.

Information when it matters

There are various measurement approaches, most of which involve passing a signal through the flow of fluid and analyzing the results. Some test how quickly sound travels through the flow, while others emit radiation and determine how much energy is absorbed.

Without accurate real-time measurement it is difficult to make good decisions. For decades the oil and gas industry has relied on multiphase flow meters that have multiple limitations. Some meters cannot provide accurate measurements when there are high water and gas flows, for example. Others are affected by changes in the salinity or temperature of the fluids. Also, none of them work in all field conditions, meaning different set-ups — or entirely different meters — will be needed at each field or group of wells.

Finding a technological solution that can fix a majority of these shortcomings is hugely valuable.

Looking to microwaves

Microwave measurement has typically been limited because it is only accurate in a narrow range of operating conditions, with specific levels of liquid or gas, for example, and the meter must be recalibrated as conditions change.

Researchers from our Exploration and Petroleum Engineering Center – Advanced Research Center (EXPEC ARC) teamed up with colleagues from King Abdullah University of Science and Technology (KAUST). Over seven years they developed a novel, microwave resonance-based multiphase meter able to provide real-time monitoring of water cut and flow.

This meter uses a digital-twin artificial intelligence model to predict flow in the pipe and compare that with our measurements, enabling our meter to automatically tune itself to wide-operating conditions and significantly reduce the need for recalibration.

Using microwaves means the meter is non-radioactive, reducing complexity and safety measures for sites using the device. It is also non-intrusive — the microwaves pass through the fluids inside the non-metallic section of the pipe — and can be used on pipes of different sizes and orientations, without needing to be inserted into the pipe. Unlike some meters, which can be installed only one way up, it can measure accurately in any orientation.

An effective tool for monitoring oil, water and gas flows

Leveraging the Fourth Industrial Revolution

The use of technologies like Digital Twin is just a part of how the new meter draws on our expertise in Fourth Industrial Revolution (4IR) technologies, such as artificial intelligence (AI), Big Data, cloud computing, blockchain, and the Internet of Things (IoT). It also uses 3D-printed parts, which are lighter and cheaper to produce than typical machine components.

The improved accuracy and reduced cost of this meter aims to significantly improve well productivity and, furthermore, may help reduce its carbon footprint, because a facility that is producing too much water will have to use additional energy to get rid of it. It is also a lower-carbon alternative to manual, portable well-testing, which requires trucks filled with equipment, and the presence of a large operation crew on the field year-round.

Creating a commercial solution

The new design was tested at our research facilities in Houston, in the United States, and at a commercial flow loop facility there, as well as by Aramco’s field engineers in Saudi Arabia. The first version of the three-phase meter was tested in April 2022 and a prototype is expected to be tested in the field in 2023. The project team has already spun out a company, with support from Aramco, to develop the meter into a commercial product.

This technology dovetails into Aramco’s 4IR infrastructure — making use of capabilities we have developed and using them to create innovative solutions to long-standing challenges, and support the digitalization of the energy industry. Besides the multiphase flow meter’s commercial potential, we have also licensed the technology to King Abdullah University for Science and Technology (KAUST) so they can explore further beneficial uses.

Future flow

Our microwave-based, multiphase flow meter has great potential to play a key role in enhancing production and improving reservoir management, helping us to operate more efficiently and continue to make the best use of our natural resources. It demonstrates the limitless possibilities of using innovative technologies to help overcome existing and new challenges in the oil and gas industry.